In the field of biomedicine, every tiny progress may bring more accurate and efficient treatment plans for patients, which is crucial for improving treatment efficiency and patient experience. 3D printing technology, as an important driving force for medical technological innovation, is changing the design, manufacturing, and personalized treatment methods of medical devices in many aspects. With its innovative PμSL technology, BMF provides strong support for customers to explore new possibilities with its excellent precision and stable tolerance control capabilities.

Micro 3D Printing Technology in Endoscopy

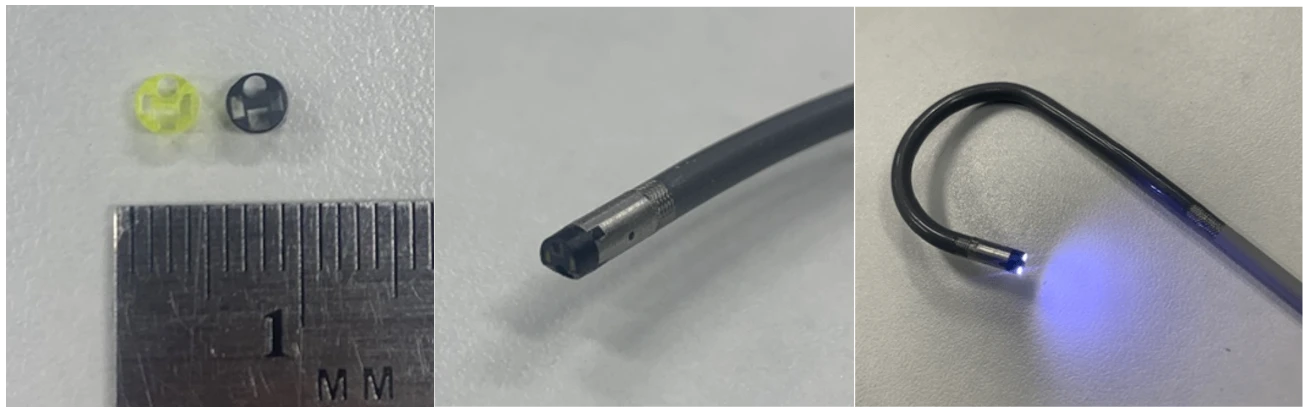

RNDR Medical, which focuses on the advancement of medical technologies, has developed a new type of disposable endoscope for urological use, facilitating direct observation and navigation for the diagnosis and treatment of urinary tract diseases, such as kidney stones and urothelial carcinoma. The key component of this device is the distal tip, which contains the camera chip and illumination source, guides the irrigation fluid path, and provides a connection from the working channel to the external anatomical environment. The design requirements for the distal tip are very strict, requiring complex 3D geometries, tight tolerances, and thin walls within a tiny diameter profile, presenting new challenges for prototype testing. BMF’s microArch series of micro-level 3D printers can achieve resolutions of 2 μm/ 10 μm/ 25 μm and tolerances ranging from ±10 μm to ±25 μm, providing a cost-effective alternative to traditional micro-molding for RNDR Medical’s design challenges. BMF’s printers enable RNDR to rapidly iterate and develop, accelerating product time to market and saving significant costs during the design and development phase.

Micrometric Fabrication Empowers the Future of Minimally Invasive Surgery

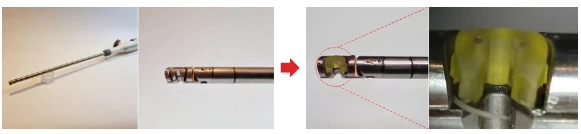

Minimally invasive surgery, favored for its minimal trauma and quick recovery, is increasingly sought after by patients. Sutrue, a UK-based medical device developer and manufacturer, its minimally invasive suturing device is designed specifically in mind for keyhole surgery – both laparoscopic and robotic. With BMF PμSL technology, allowing for Sutrue to try different parts to find the ideal fit and achieve finally function as designed without the cost and time delay of machining the part.

PμSL Enables the Development of New Skin Cancer Treatment Devices

In the field of skin cancer treatment, IMcoMET has developed an innovative immunotherapy aimed at changing the tumor microenvironment to treat skin cancer. With the help of BMF’s high-precision 3D printing technology, IMcoMET is able to manufacture microneedle array components for its M-Duo® technology, and adjust their needles as they wish.BMF can achieve very high print resolutions – between 2 and 50 microns – as well as tolerances of between ±10 and ±25 microns, this technology is used to manufacture the components including two parallel channels spaced 20-40 μm apart, each with a 100 μm diameter. providing critical support for IMcoMET’s technological miniaturization.

As a pioneer and leader in the field of micro 3D printing, BMF possesses a world-leading ultra-high precision printing system, that is widely applicable to precision medical devices, precision electronic devices, and many other fields. If you are interested in BMF products or printing services, please contact us and the BMF professional team will discuss it with you.