Transforming patient-speific vascular geometries into functional microfluidic devices has long been a challenge, hindered by complex workflows and long fabrication cycles. A new study published in Advanced Materials by Professor Arnold Ju’s team at the University of Sydney presents a breakthrough: an automated, high-precision platform that fabricates patient-specific vascular chips in under two hours—a process that traditionally required more than ten.

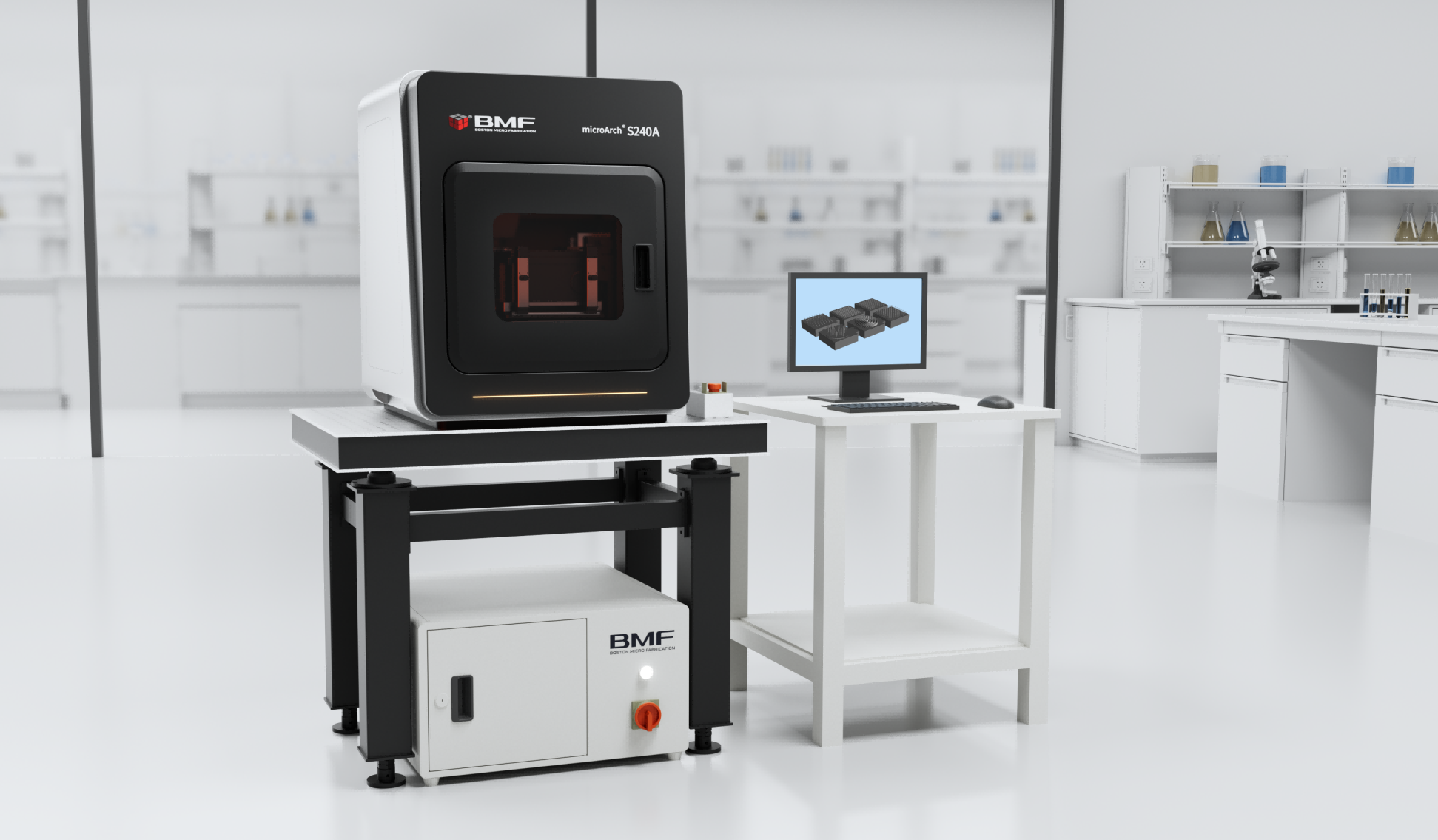

At the heart of this innovation is BMF’s Projection Micro Stereolithography (PμSL) technology, deployed through the microArch® S240 system with 10 μm resolution. By optimizing photopolymerization parameters and integrating advanced surface chemistry modifications, the team achieved not only exceptional anatomical accuracy but also near 100% manufacturing success rates.

| Precision, Speed, Reliability

The optimized printing workflow faithfully reproduces complex vascular features such as stenosis, bifurcation, and ulceration. Chemical surface treatments improved biocompatibility and endothelial cell adhesion, while modular design significantly reduced operator dependency. Collectively, these advances enable researchers to replicate intricate vascular structures with unprecedented efficiency and reproducibility.

| From a Specialized Tool to a Versatile Research Platform

The resulting vascular chips support both cell culture and hemodynamic simulation, creating realistic microenvironments for thrombosis studies, drug testing, and personalized treatment strategies.

Even when scaled down 30×, the chips maintained shear stress distributions comparable to real human vessels, as confirmed by computational fluid dynamics (CFD). This makes the platform broadly applicable to different vascular disease models—including coronary and cerebral arteries—and establishes it as a scalable tool for both research and translational medicine.

| A Milestone for Personalized Medicine

Professor Arnold Ju noted:“Our collaboration with BMF enabled a critical breakthrough in manufacturing technology. This platform offers new possibilities for precision medicine and vascular device development, and we believe it will accelerate both disease understanding and personalized therapy design.”

This study demonstrates how high-resolution 3D printing can bridge the gap between imaging data and functional organ-on-chip models, marking a milestone for patient-specific, biomimetic platforms.

DOI:https://doi.org/10.1002/adma.202508890