As microfluidic systems evolve toward higher functional integration and greater sensing accuracy, manufacturing precision has become a defining factor in device performance. In particular, applications such as single-cell impedance spectroscopy demand not only micron-scale resolution, but also the ability to seamlessly integrate structures with vastly different feature sizes into a single, monolithic device. This is where dual-precision micro 3D printing is emerging as a critical enabler.

Recent collaborative research from The University of Manchester and The University of Melbourne demonstrates how dual-precision 3D printing can directly translate into measurable improvements in microfluidic sensing performance. By leveraging BMF’s microArch® D1025 dual-precision 3D printing system, the team fabricated a complex microfluidic chip featuring an integrated nozzle architecture that enables tunable three-dimensional hydrodynamic focusing—significantly enhancing impedance spectroscopy signal quality.

.png)

Why Dual Precision Matters in Microfluidic Device Design

Microfluidic chips for electrical sensing typically combine structures at very different length scales. Narrow nozzles, contraction regions, and sensing zones often require feature sizes on the order of tens of micrometers, while inlet channels, reservoirs, and support structures must remain mechanically robust and span hundreds of micrometers or more. Conventional fabrication approaches force designers to compromise—either sacrificing fine detail or increasing process complexity through multi-step lithography, alignment, and bonding.

Dual-precision 3D printing overcomes this limitation by allowing different resolutions to coexist within the same printed part. With BMF’s dual-precision architecture, high-resolution regions can be printed at 10 μm precision, while larger structural features are produced at 25 μm precision, all within a single build. This capability preserves geometric fidelity where it matters most, while maintaining efficiency and stability at larger scales.

Enabling Integrated Nozzle-Based 3D Flow Focusing

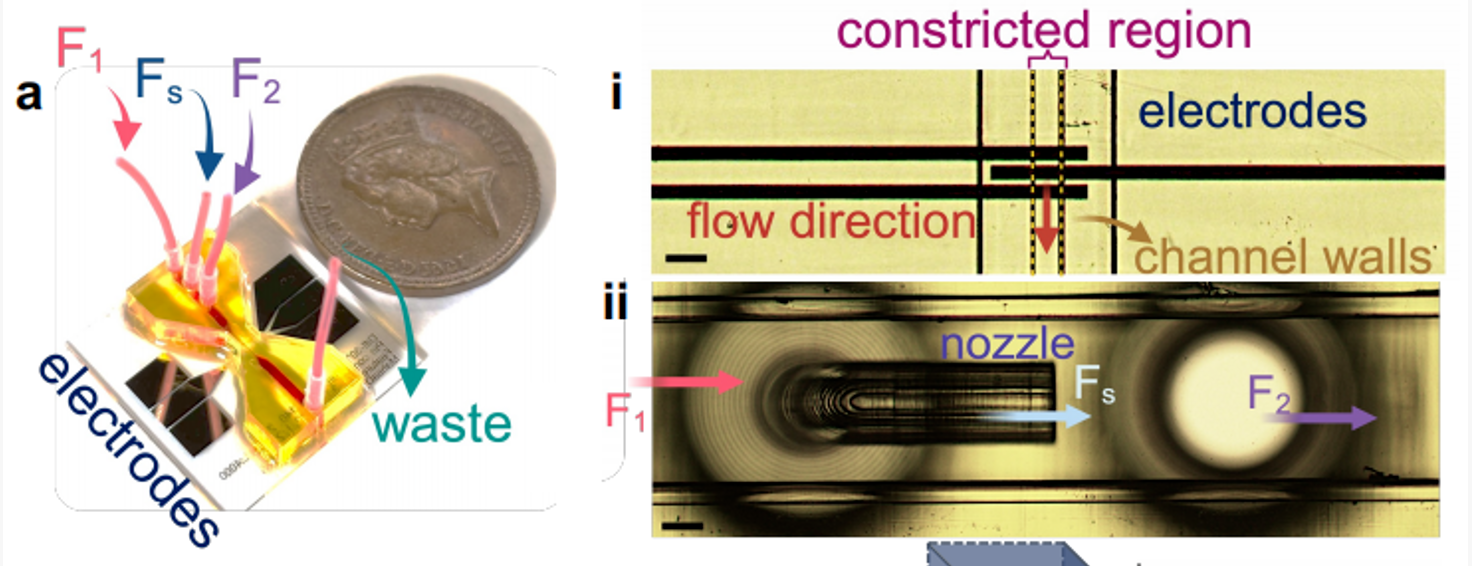

In this study, the dual-precision approach was essential for realizing an integrated nozzle structure designed to actively lift the sample stream away from the channel floor. The printed microfluidic chip combines a 120 μm-radius nozzle, an 800 μm-wide main channel, and a 100 μm-wide downstream contraction, all fabricated monolithically using HTL resin.

Such a geometry would be extremely challenging to achieve using traditional planar microfabrication methods, which rely on stacked layers and precise bonding. By contrast, the projection micro stereolithography (PμSL) process used in the microArch® D1025 system enables true three-dimensional freedom, allowing vertical and lateral features to be defined with high accuracy in a single print.

This geometric freedom directly supports the device’s two-stage sheath flow strategy. The nozzle and upstream sheath flow provide lateral and partial vertical focusing, while a secondary top sheath flow and downstream contraction reinforce vertical confinement. The result is a tightly controlled three-dimensional particle trajectory through the sensing region.

From Manufacturing Precision to Measurement Performance

The impact of dual-precision fabrication extends beyond structural elegance—it directly improves sensing outcomes. Numerical simulations and experimental validation show that by adjusting flow rate ratios, particles can be positioned within 10 μm of the coplanar electrodes, without relying on shallow channels or complex electrode layouts.

Fluorescence imaging confirms stable lateral and vertical focusing across a wide range of operating conditions, while impedance measurements reveal a strong correlation between vertical particle position and signal amplitude. At an optimized flow ratio, the system achieves a peak signal-to-noise ratio of 17.38 dB, with significantly reduced signal variability. This level of performance underscores how manufacturing accuracy at the micro-scale can translate into higher measurement fidelity and reproducibility.

Simplifying Fabrication While Expanding Design Freedom

Beyond performance gains, dual-precision 3D printing also streamlines the fabrication workflow. The ability to print complex nozzle structures and contraction regions in a single step eliminates the need for multi-layer alignment and bonding, reducing fabrication time and potential failure points. For researchers and device developers, this means faster iteration cycles, lower prototyping costs, and greater freedom to explore unconventional geometries.

The microArch® Dual series (D0210 and D1025) further extends these advantages by supporting precision switching both within the same layer (XY) and across different layers (Z), while maintaining ultra-tight tolerance control. Combined with an automatic leveling system, the platform delivers industrial-grade stability and repeatability across a build range spanning 2 μm features to 100 mm × 100 mm × 50 mm structures.

A Platform for Next-Generation Microfluidic Innovation

As precision medicine, advanced diagnostics, and lab-on-a-chip technologies continue to advance, the demand for microfluidic devices with higher integration and tighter control will only increase. Dual-precision micro 3D printing provides a powerful manufacturing foundation for this evolution—bridging the gap between design ambition and practical fabrication.

By enabling researchers to translate complex 3D designs directly into functional devices, BMF’s dual-precision PμSL technology is helping redefine what is possible in microfluidic sensing, from impedance cytometry and chemical analysis to next-generation biomedical and analytical systems.

Reference: Sensors and Actuators B: Chemical (2025),“Precision flow focusing in 3D printed microchannels for enhanced impedance spectroscopy”

DOI: 10.1016/j.snb.2025.139050