Electronic skin (E-skin) is a critical enabler for dexterous robotic hands, forming the foundation of tactile perception, intelligent decision-making, and adaptive human–machine interaction. By mimicking the human sense of touch, E-skin allows robots to perceive pressure, texture, and motion—capabilities essential for applications ranging from surgical assistance to precision industrial manipulation.

However, most existing E-skin solutions face fundamental limitations. They typically offer limited sensing functions, rely on complex fabrication processes, and struggle to scale to large areas while maintaining high resolution and mechanical robustness. These challenges make it difficult to deploy E-skin systems in real-world, high-precision scenarios where adaptability, reliability, and manufacturability are equally critical.

To overcome these barriers, researchers worldwide have explored new sensing mechanisms and manufacturing approaches. Triboelectric nanogenerators (TENGs) have emerged as a promising solution due to their self-powered operation, high sensitivity, and rich signal output. At the same time, additive manufacturing offers a pathway toward customizable, scalable, and cost-effective production. Yet, integrating high-performance sensing materials, scalable manufacturing technologies, and AI-driven data interpretation into a single, fully functional E-skin system remains a significant challenge.

The Breakthrough: All-Printed, AI-Enabled Triboelectric E-Skin

A collaborative research team led by Prof. Feng Gong and Associate Prof. Hui Li from Shenzhen University, together with Prof. Lelun Jiang from Sun Yat-sen University, introduced an innovative solution: an AI-powered, fully printed, stretchable triboelectric electronic skin (TE-Skin) enabled by Interface-Constrained Coaxial Printing (ICCP).

This integrated approach combines large-area manufacturability, multifunctional sensing, and intelligent signal decoding, enabling seamless deployment across fingertips, palms, and the back of dexterous robotic hands. The result is a single E-skin platform capable of tactile imaging, material recognition, user authentication, and gesture-based control.

The research was published in Advanced Functional Materials under the title:

“An AI-Powered, All-Printed, Scalable, Stretchable Triboelectric E-Skin for Multifunctional Perception in Dexterous Hand.”

Integrated Design: High-Density Sensing with Full-Area Adaptability

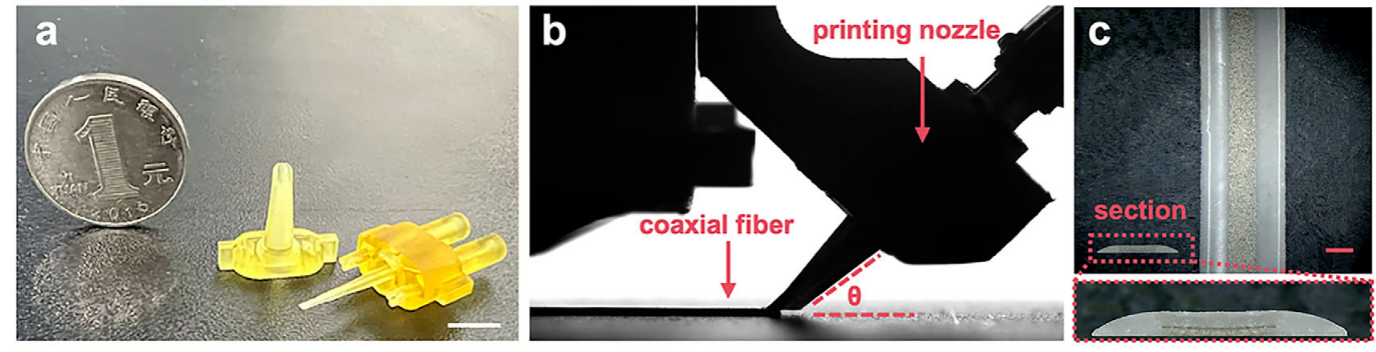

At the core of this innovation is a fully integrated design philosophy that addresses both functional integration and conformability. Using ICCP, the team fabricated an ultra-thin, high-density sensing array with a thickness of approximately 190 μm and a resolution of 11.25 dpi.

This architecture enables two key advantages:

Full-area coverage: The E-skin can conform seamlessly to complex surfaces such as fingertips, palms, and knuckles without performance degradation.

Multimodal sensing: Each sensing unit supports simultaneous functions, including pressure mapping and motion trajectory recognition.

By combining full-area adaptability with multifunctional integration, the TE-Skin overcomes the long-standing industry trade-off between sensing resolution, flexibility, and coverage.

Scalable Manufacturing Enabled by BMF’s PμSL Technology

A critical enabler of this breakthrough is BMF’s Projection Micro Stereolithography (PμSL) technology.

Using a microArch® S140 system (10 μm resolution), the research team 3D printed customized coaxial printing nozzles with exceptional precision. These nozzles were essential for implementing the ICCP process, transforming conventional cylindrical coaxial fibers into ultra-thin, ribbon-like structures—with a thickness roughly one-sixth of a standard coin.

Key manufacturing advantages enabled by BMF PμSL include:

High structural fidelity: Micron-level accuracy ensures consistent sensor geometry and reliable electrical performance.

Mechanical robustness: The printed E-skin maintains stable signal output under stretching, bending, and twisting, meeting the demands of real-world robotic applications.

By bridging micro-scale precision with macro-scale production, BMF PμSL technology provides a solid foundation for transitioning electronic skin from laboratory prototypes to engineering-ready systems.

From Research to Real-World Robotics

By combining AI intelligence, triboelectric sensing, and BMF’s micro-scale additive manufacturing, this work demonstrates a practical pathway for deploying multifunctional electronic skin in advanced robotic systems.

The synergy between ICCP and BMF PμSL technology enables electronic skin that is not only high-performance and multifunctional, but also scalable and manufacturable—key requirements for real-world adoption in robotics, healthcare, and intelligent automation.

As electronic skin continues to evolve from experimental research to industrial deployment, micro-precision 3D printing will play an increasingly vital role in shaping the next generation of human-like robotic perception and interaction.

Journal reference: Advanced Functional Materials

DOI: 10.1002/adfm.202527673