When it comes to healthcare innovation, some of the most powerful breakthroughs are happening at the micro-scale. One of the best examples is microneedle technology—tiny, painless needles designed for drug delivery, diagnostics, and advanced skin treatments. Now, with the help of micro 3D printing, microneedles are entering a new era of precision, performance, and scalability.

What Are Microneedles?

Microneedles are miniature needle-like structures, typically ranging from tens to hundreds of microns in length. Unlike traditional hypodermic needles, they are designed to penetrate just the outermost layer of the skin (the stratum corneum) without reaching deeper pain receptors.This unique property makes microneedles:

· Painless :minimizing patient discomfort.

· Safe : reducing risk of infection and tissue damage.

· Efficient: enabling drugs, vaccines, and biomolecules to be delivered directly where they are needed.

They are already being studied for vaccine delivery, insulin administration, cosmetic treatments, and continuous health monitoring.

Enabling Technology: Projection Micro-Stereolithography (PµSL)

Traditional methods of fabricating microneedles—such as etching, molding, or lithography—often face limitations in design complexity, customization, and turnaround time. BMF’s Projection Micro-Stereolithography (PµSL) platform changes the game with up to 2 μm resolution, PµSL enables:

- Design Freedom: Ability to create diverse microneedle geometries (solid, hollow, porous, or even bio-inspired designs).

- High Precision: Sub-micron resolution ensures sharp tips and smooth sidewalls for reliable skin penetration.

- Material Versatility: Compatibility with biocompatible polymers, hydrogels, and ceramics for different medical use cases.

- Rapid Iteration: From prototype to small-batch production without costly retooling.

This precision manufacturing approach overcomes the traditional compromise between sharpness, strength, and biocompatibility, giving researchers and companies the tools to accelerate microneedle innovation.

Applications at the Micro-Scale

- Bioinspired Microneedle Patch for Oral Health

Bacterial infectious stomatitis (BIS) is a painful and recurrent oral disease, where conventional treatments often fail due to the complex, constantly changing environment inside the mouth.

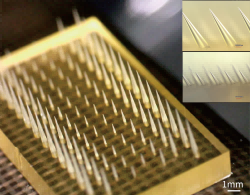

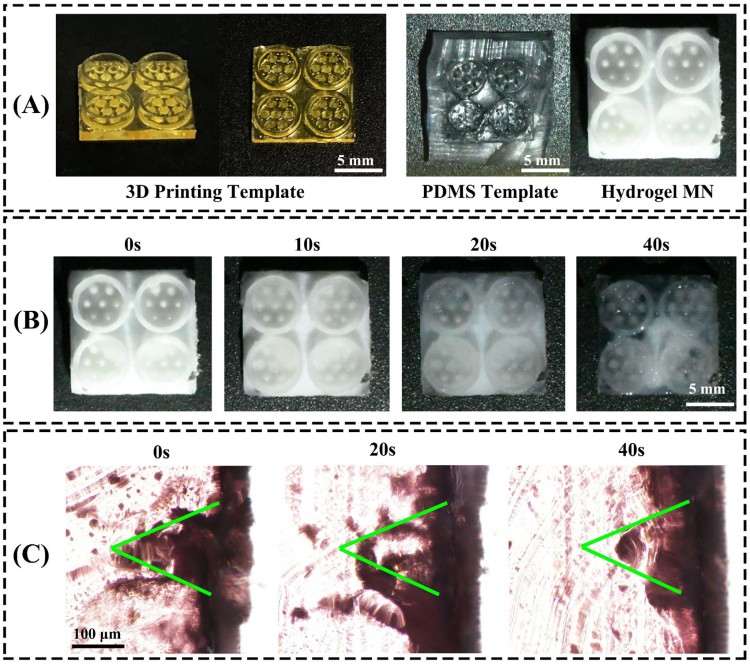

A research team at Lanzhou University has introduced a breakthrough solution: a bioinspired microneedle hydrogel patch(DOI:https://doi.org/10.1002/advs.202500432). Inspired by the adhesive structures of fruit flies, this patch combines antimicrobial hydrogels with suction-cup-like microneedle arrays to achieve strong adhesion, controlled release, and effective local therapy in moist oral environments.

At the core of this innovation is BMF’s Projection Micro-Stereolithography (PµSL) technology. Using the microArch® S230 system (2 μm resolution), the team precisely replicated sub-micron adhesive structures, ensuring reliable performance and scalability.

This achievement showcases how micro 3D printing empowers next-generation oral therapeutic devices—enabling stable, targeted treatment and paving the way for smarter, more effective patient care.

2. Mitochondria-Targeted Microneedles

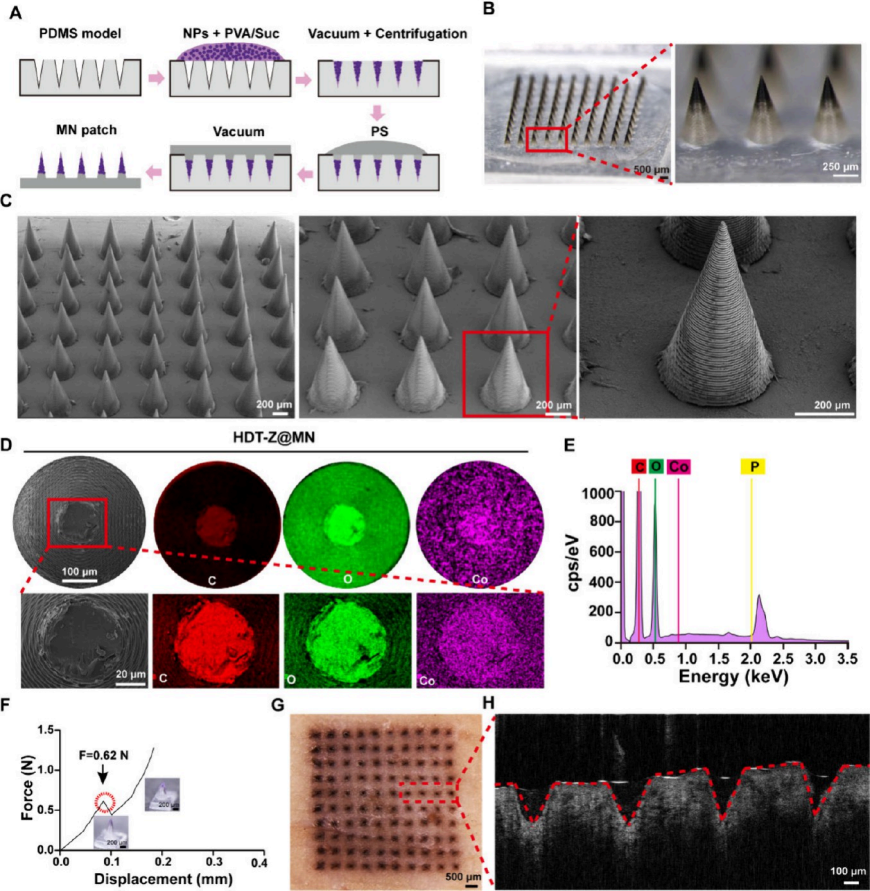

A research team from Wuhan University has proposed an innovative strategy to overcome drug resistance in breast cancer(DOI:https://doi.org/10.1021/acsnano.5c06302). The team developed a mitochondria-targeted microneedle system (HDT-Z@MNs) designed to precisely activate the “death switch” of cancer cells, effectively breaking through the resistance barrier of doxorubicin.

The microneedle arrays required for the experiments were fabricated using BMF’s microArch® S240 system (with a printing resolution of 10 μm), followed by replication through PDMS molding. The microneedle array was arranged in a 10 × 10 pattern, with each needle measuring 850 μm in height, 400 μm in base diameter, and 700 μm in spacing.This workflow not only demonstrates the high controllability and safety of microneedle systems, but also validates mitochondria as an emerging therapeutic target for multi-modal synergistic cancer therapy.

This pioneering study provides a new therapeutic pathway for breast cancer and other drug-resistant solid tumors, highlighting the potential of micro 3D printing to accelerate translational medicine.

Conclusion

Microneedles represent a bridge between biology and technology. They embody the promise of minimally invasive, patient-friendly healthcare solutions. As micro 3D printing continues to mature, the path forward includes personalized medicine, tailoring microneedle patches for individual patients. And multi-functional devices, combining drug delivery with biosensing.

From vaccine delivery in global health to smart wearables in precision medicine, microneedle 3D printing is poised to reshape how we think about treatment, monitoring, and care.

Learn more about how BMF’s micro 3D printing technology is empowering the future of medical innovation.