In the field of healthcare, the application of innovative technology has always been a key force in driving industry development. BMF provides customized solutions for biomedicine, using ultra-high precision 3D printing technology to bring patients more effective treatment options and a better quality of life experience.

Wound infection is a common problem during the healing process, which can lead to a long healing process or incomplete healing of chronic infected wounds. Traditional treatment methods include wound debridement, oral antibiotics, and antimicrobial dressings, but they have limitations, such as the physical barrier formed by biofilms, the risk of antibiotic resistance, and the pain caused by frequent dressing changes.

Innovative Microneedle Technology Accelerating Wound Healing

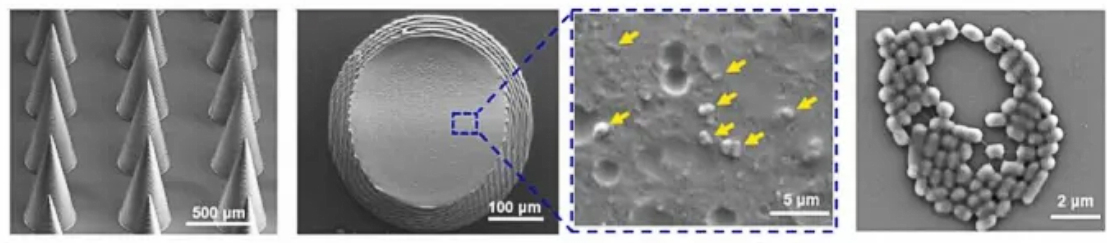

Based upon this, a research team from the School of Pharmaceutical Sciences at Wuhan University has developed a probiotic-based living microneedle patch, which was manufactured by using BMF’s microArch® S240 3D printing system, with a precision of 10μm for the molding process, and then prepared through PDMS.

The result has been described as “Accelerated infected wound healing by probiotic-based living microneedles with long-acting antibacterial effect” published in the journal Bioactive Materials.

The microneedle patch is made of polyvinyl alcohol (PVA), sucrose, glycerol, and Lactobacillus reuteri. The PVA-sucrose matrix provides mechanical strength, promotes the rapid dissolution of microneedles after skin insertion, and achieves bacterial delivery. Lactobacillus reuteri to metabolize glycerol and produce an antibacterial substance called reuterin, which has the effects of antibacterial, reducing inflammation and promoting wound healing. Glycerol not only does not affect the survival of L. reuteri, but also provides a source for its continuous production of L. reuteri. This innovative technology improves therapeutic efficiency and makes the treatment process more comfortable for patients.

Precision Manufacturing Redefining Healthcare

BMF’s microArch® S240 (10μm resolution), with its top-notch precision and stability, provides strong support for the manufacturing of medical products. The ultra-high precision ensures that every detail of the microneedle patch meets the design requirements, ensuring the quality and efficacy of the product. This ultimate pursuit of precision is BMF’s commitment and contribution to the field of healthcare.

3D Printing Technology Opening a New Chapter in Personalized Medicine

3D printing technology, with its personalization, flexibility, and innovation, has brought revolutionary changes to the medical field. BMF has not only demonstrated the advantages of this technology in the manufacturing of microneedle patches, but also demonstrated the unlimited possibilities of 3D printing technology in personalized medical devices, complex-structured implants, and customized treatment plans.

The cooperation between BMF and the School of Pharmaceutical Sciences at Wuhan University is a model of industry-academia-research integration. We will jointly promote technological progress and industry development in the field of healthcare. BMF looks forward to cooperating with more research institutions, medical institutions, and enterprises to explore new applications of 3D printing technology in the field of healthcare.

Click here to contact us.

For more details about this research: