Keratitis is an inflammation of the cornea, mainly caused by injury, bacteria and viruses. Keratitis can be divided into two categories: non-infectious and infectious, the latter can lead to serious complications that may permanently damage your vision. Traditionally, the most common treatment for infectious keratitis is using antibiotic eye drops on the ocular surface to combat infectious bacteria. However, bioavailability and drug retention time are significantly reduced by the epithelial barrier on the cornea, which prevents hydrophilic drug molecules from penetrating the cornea. Additionally, the lachrymal will dilute the drug solution, further diminishing its effectiveness. Therefore, several strategies have been explored to improve drug permeability and extend drug residence time in the cornea, which may lead to toxic effects on ocular tissues and increase the risk of antimicrobial resistance. Treatment of keratitis depends on the cause of the inflammation or infection. Hence, the aforementioned challenges make the development of an innovative intraocular drug delivery system for keratitis treatment urgent.

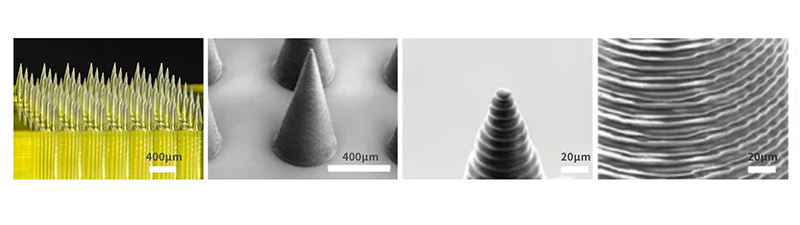

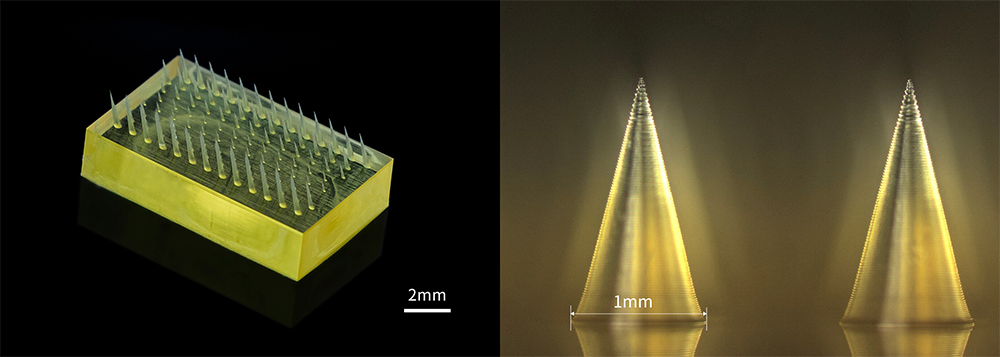

Microneedles (MNs) are micron-sized structures that can penetrate physiological barriers and enable sustained drug delivery. Therefore, a research team from the School of Pharmaceutical Sciences at Wuhan University has proposed a self-implantable core-shell microneedle (MN) patch for the long-acting treatment of bacteria-induced keratitis. The related research results were published in the journal Small under the title “Self-Implantable Core-Shell Microneedle Patch for Long-Acting Treatment of Keratitis via Programmed Drug Release”. This microneedle patch was prepared by a sequential casting method in a PDMS mold after being fabricated by a BMF microArch® S240 micro 3D printer. The unique structure of this patch provides stable protection for the Active Pharmaceutical Ingredients in the core layer, ensuring intraocular drug delivery instead of dissolving on the corneal surface. Compared to conventional treatments, this approach shows promise for effectively treating bacteria-induced keratitis.

Advances in precision medicine have already led to high-precision technology and approved treatments that are tailored individually. The capability of BMF high-resolution and micro-precision technology makes micro-3D printing ideal for precision medicine applications. Besides the self-implantable core-shell microneedle patch mentioned above, other applications include customized flexible hollow microneedles for psoriasis treatment, multifunctional microneedle patches for chronic wound healing, and dissolving microneedle patches for long-acting hair regrowth therapy. In these applications, researchers aim to build effective precision models and provide new devices that will improve patient care and recovery in precision medicine. By harnessing the capabilities of BMF high-resolution and PμSL technology, precision medicine devices can be optimized for effectiveness.

For additional information, you may read the complete research paper here.

https://doi.org/10.1002/smll.202310461

If you would like to cooperate with us in precision medicine or other industries that require high-precision machining, please contact us for further discussions.