Dual-mode flexible capacitive sensors that integrate proximity sensing and tactile perception are rapidly becoming a cornerstone technology for next-generation human–machine interaction. These sensors enable robots and intelligent systems to perceive their surroundings more comprehensively and to interact with objects in a safer, more intuitive manner.

However, conventional dual-mode capacitive sensors still face critical performance bottlenecks. In non-contact sensing mode, limited fringe electric fields at electrode edges restrict sensing distance. In contact mode, homogeneous dielectric layers and material stiffness often lead to deformation saturation under high pressure, resulting in nonlinear sensitivity and reduced measurement accuracy. Addressing these challenges requires not only innovative sensor architectures, but also manufacturing technologies capable of reproducing complex micro-structured designs with high precision and repeatability.

Research Breakthrough Enabled by PμSL Technology

A research team led by Prof. Yuxia Li at Shandong University of Science and Technology recently reported a significant advance in this area in Chemical Engineering Journal. The study, titled “Flexible dual-mode capacitive sensor based on snowflake-like flowable electrode and multi-level microstructured dielectric layer with long proximity sensing distance and high linear sensitivity”, demonstrates how structural innovation combined with micro-scale fabrication can dramatically enhance sensor performance.

The proposed sensor architecture leverages a snowflake-like liquid metal electrode design to amplify fringe electric field effects, extending the proximity sensing distance to 100 mm. At the same time, a multi-level microstructured dielectric layer delivers highly linear pressure sensitivity (R² = 0.98749) across a wide detection range of 0–320 kPa. This unique combination enables long-range non-contact detection and high-fidelity tactile sensing within a single flexible device.

BMF’s PμSL Technology: Turning Complex Sensor Designs into Reality

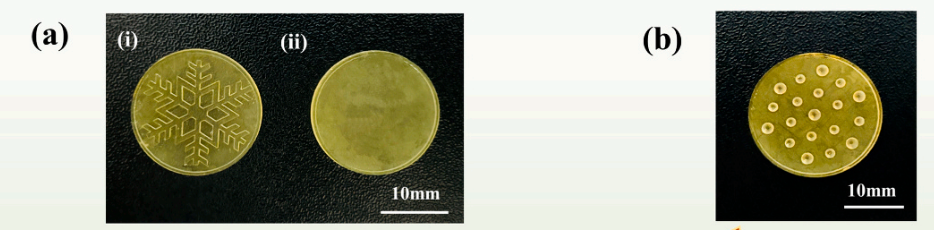

The realization of this advanced sensor architecture was made possible by BMF’s Projection Micro-Stereolithography (PμSL) technology. Using the microArch® S240 system with 10 μm resolution, the research team fabricated both the snowflake-like electrode molds and the multi-level microstructured dielectric molds with exceptional geometric accuracy.

Figure1.Snowflake-like electrode molds and the multi-level microstructured dielectric moldsprinted with BMF 3D printers

PμSL offers key advantages for sensor R&D:

- High-resolution micro-structuring, enabling intricate electrode edges and hierarchical dielectric feature

- Design-to-print fidelity, ensuring that simulated sensor performance translates into physical devices

- Material and process flexibility, supporting soft polymers and complex mold geometries required for flexible electronics

By enabling reliable fabrication of multi-scale microstructures, PμSL bridges the gap between theoretical sensor design and experimental validation.

Optimized Structure for Superior Sensing Performance

The sensor adopts a sandwich-type configuration: two snowflake-like liquid metal electrodes encapsulate an Ecoflex dielectric layer patterned with multi-level semi-cylindrical microstructures. The flowable electrode design significantly enhances edge electric fields, improving proximity sensing performance for applications such as safe human–robot interaction and non-contact motion tracking.

Meanwhile, the multi-level dielectric microstructures ensure more uniform stress distribution under applied pressure. Larger micro-features respond sensitively to low pressures, while smaller features dominate deformation under higher loads. Together, they deliver a complementary response across the full pressure range, resulting in high linearity and stable sensitivity in tactile sensing mode.

To demonstrate practical applicability, the research team showcased multiple use cases, including Morse code signal transmission, human–robot safety warning systems, and non-contact trajectory tracking using a 3×3 sensor array. These demonstrations highlight the sensor’s potential in gesture recognition, intelligent robotics, and interactive electronics.

Enabling the Next Generation of Intelligent Sensing

This work clearly demonstrates how BMF’s PμSL micro-scale 3D printing technology empowers advanced sensor innovation. By enabling the precise fabrication of complex electrode geometries and hierarchical micro-structured dielectrics, PμSL provides sensor researchers with the freedom to explore new design spaces and performance frontiers.

As flexible electronics, robotics, and intelligent perception systems continue to evolve, PμSL-enabled manufacturing is becoming a critical tool for translating breakthrough sensor concepts into functional, scalable prototypes—accelerating innovation across human–machine interaction, smart robotics, and advanced sensing applications.

Reference: Chemical Engineering Journal, DOI: 10.1016/j.cej.2025.172401