Shenzhen, China — November 11, 2025 — BMF APAC has officially released the microCube T10, a new desktop-class micro 3D printing system featuring 10.8 μm optical precision. Designed to make high-resolution microfabrication accessible to more research teams and small enterprises, the T10 combines lab-grade accuracy with a compact, easy-to-use desktop form factor.

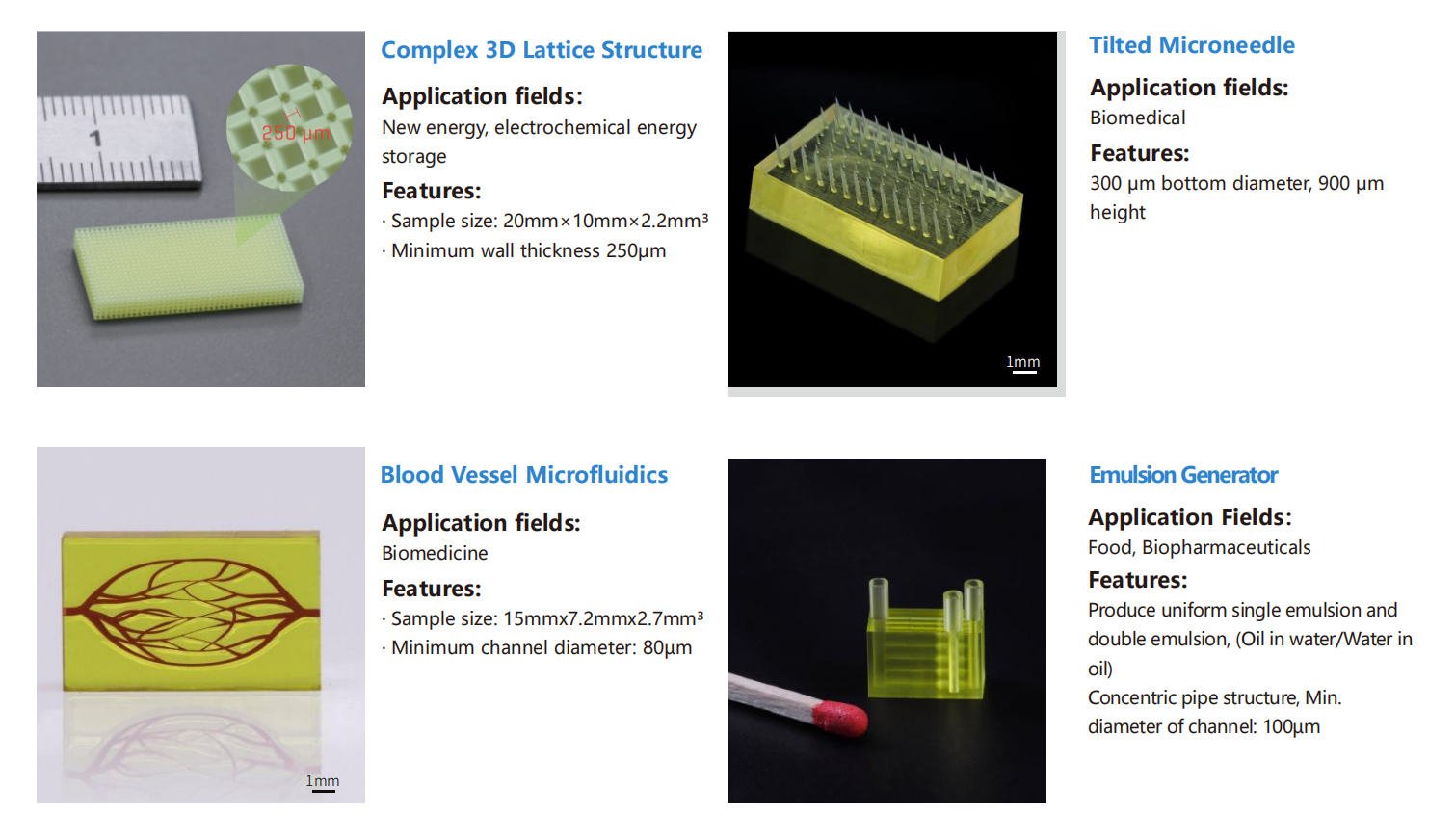

Equipped with BMF’s printing technology, the T10 ensures high-fidelity printing of delicate microstructures such as microfluidic channels and biomedical scaffolds. It supports multiple materials including photopolymers, ceramics, hydrogels, and biomaterial—enabling a wide range of R&D applications from microelectronics to regenerative medicine.

With intuitive touchscreen control, offline operation, and a material-saving mode requiring only 2–5 mL of resin, the microCube T10 redefines convenience and cost-efficiency in high-resolution additive manufacturing.

Meeting the Next Wave of Miniaturization

As artificial intelligence, new energy, and biomedical engineering accelerate technological advancement, miniaturization and integration have become defining trends. However, conventional manufacturing approaches often struggle to meet the complexity and precision required for today’s micro devices.

The microCube T10 addresses this challenge by combining high precision with a desktop-friendly design.It provides high-resolution, high-tolerance control in a simplified and cost-efficient format, ideal for early-stage R&D, academic research, and functional prototyping.

Key Highlights

- 10.8 μm Optical Precision:The T10 achieves an exceptional 10.8 μm optical resolution, enabling fabrication of microstructures with fine features and high dimensional accuracy—ideal for applications such as microfluidic devices, micromechanical components, and miniaturized medical tools.

- Multi-Material Compatibility:The microCube T10 supports photopolymer resins, ceramic slurries, bioinks, and hydrogels, expanding its applicability from microelectronics and aerospace components to biomedical scaffolds and lab-on-chip systems.

- Desktop Design for Flexible Workspaces:Compact and easy to install, the T10 fits seamlessly into laboratory environments, providing researchers with an efficient, high-performance platform for precision additive manufacturing.

Redefining the User Experience

- Micro High Resolution: Desktop high resolution micro 3D printing system with optical resolution 10.8μm

- Fast Curing Test:High-efficiency test parameter combination, adjustable parameters during printing.

- Supports Offline Work:No computer connection required,USB flash drive printing is supported.

- Precision Scraper System:Adjustable scraper for auxiliary spreading to eliminate bubbles generated during the printing process

- Touch screen control:Equipped with a 7-inch touchscreen for customizing print parameters and modes

- Oxygen-permeable membrane printing mode:Lower release force, suitable for hydrogel

- Material-saving mode:2-5ml is enough to start printing

- Bio-printing:Supports hydrogel and active bio-ink printing

By offering professional-grade precision in a compact form, the T10 brings microfabrication closer to real-world applications, accelerating the translation of ideas into tangible products, enabling researchers and engineers to explore micro scale innovation in Microfluidics, Biomedical research, Ceramic microstructures, Precision optics, or other fields.

Availability

The microCube T10 is available exclusively in the Asia-Pacific (APAC) region.Researchers and organizations outside APAC can explore BMF’s global product portfolio and request regional availability updates via the official website.

Learn more about the microCube T10

Contact us: bmf@bmftec.cn

About BMF

BMF is a global pioneer in micro scale additive manufacturing. The company’s patented Projection Micro Stereolithography (PµSL) technology enables ultra-high-precision 3D printing for applications across biomedical engineering, electronics, optics, aerospace, and advanced materials.

BMF continues to push the limits of microfabrication, empowering innovators worldwide to bridge the gap between prototypes and production.