Tolerances refer to the permissible range of dimensional deviations during the manufacturing process, directly affecting the performance, quality, and reliability of products. As products become increasingly miniaturized and precise, higher demands are placed on the ability to control over tolerances. BMF, with its revolutionary Projection Micro Stereolithography (PµSL) technology, is redefining the standards of precision manufacturing, bringing unprecedented innovative solutions to various industries.

Importance of Tolerance Control

Tolerances are essential for ensuring consistency and reliability in the design, manufacturing, and use of products. Whether in medical devices, precision electronics, or consumer electronics, tolerances play a key role. For instance, in the medical field, tight tolerance ensures the effectiveness and safety of drug delivery systems; in the electronics industry, it guarantees the perfect fit and performance of connectors and circuit boards.

PμSL Technology: Ultra-High Precision and Tight Tolerance

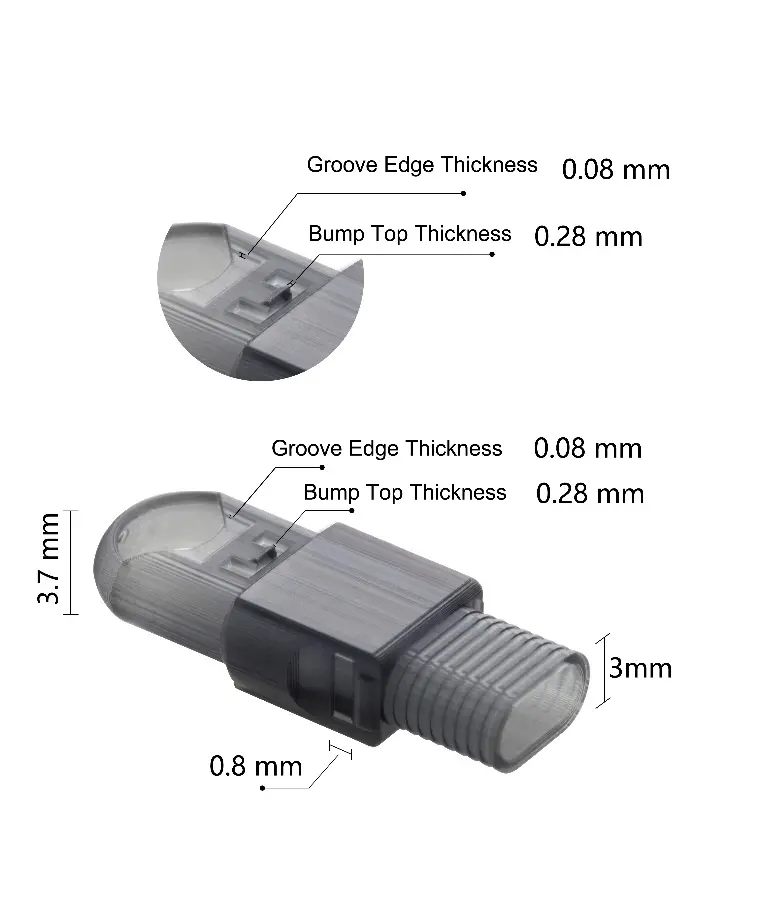

BMF’s PµSL technology can consistently produce individual or batch products with tight tolerance up to ±10 μm. This precision, especially when the product details reach the micron level, is a major prerequisite for ensuring that the production parts fit perfectly with other components.

Customized and Efficient Solutions

BMF technology has a wide range of applications,, from microchips and electronic circuits in consumer electronics, to micro-needle patches and miniature surgical tools in medical devices, and to the precision manufacturing of electronic connectors. BMF technology can provide customized solutions that not only shorten product development cycles and reduce costs, but also provide greater space for innovation.

BMF’s Professional Commitment

BMF is committed to a strict quality assurance process for each product to ensure that each part meets the customer’s specifications. This persistent pursuit of precision and quality has made BMF one of the trusted partners in the medical, electronics and consumer products industries.

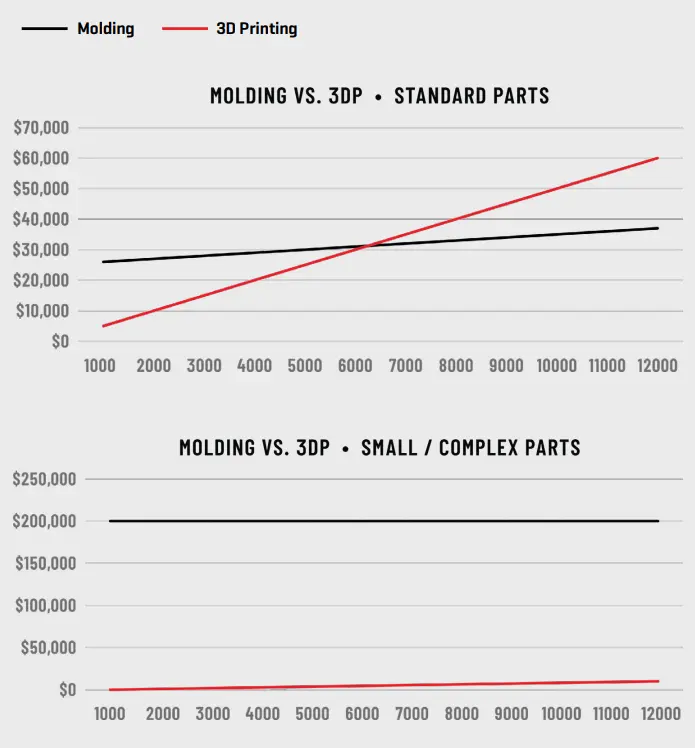

Figure: The line graphs illustrate the cost by quantity of manufacturing both standard and small, complex parts by either molding or 3D-printing

As technology continues to advance, BMF will continue to push the boundaries of precision manufacturing, helping enterprises to achieve more efficient, reliable, and innovative product manufacturing. Choosing BMF means choosing a partner that can provide truly precise manufacturing solutions.

To learn more about how BMF can help your business enhance product quality and innovation capabilities, contact us and explore the future of precision manufacturing together.