What if the next generation of sensors could not only measure but also conform, adapt, and intelligently respond to complex, dynamic environments? Flexible sensors represent one of the most critical enablers for emerging technologies in wearable health monitoring, soft robotics, human–machine interfaces, and next-generation electronics.

This is where micro-scale 3D printing is making a decisive impact. By offering sub-micron resolution, design freedom, and material versatility, advanced additive manufacturing allows researchers to engineer sensors at the structural level.They can now fabricate bioinspired, three-dimensional microstructures, such as microneedle arrays, micropillars, and sinusoidal micro-patterns that endow flexible sensors with unprecedented stability and responsiveness.

The Shift Toward Smart Flexible Sensors

Flexible sensing technologies are crucial for advancing intelligent systems, from wearable robotics to embedded health monitors. But designing devices that are both robust and responsive can be tricky: traditional multilayer sensors often suffer from weak interfaces, reduced sensitivity under deformation, and delamination under mechanical stress.

Thanks to micro 3D printing unmatched precision and material versatility, it enables complex interface geometries that fuse structure and function, helping devices stay tough, reactive, and reliable under real-world conditions.

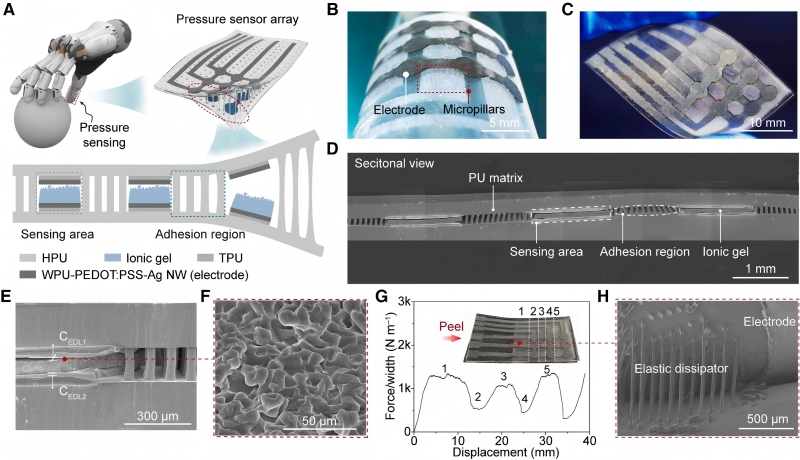

How Micron-Scale 3D Printing Enhances Sensor Interfaces

Flexible tactile sensors are key components for building intelligent robots, wearable devices, and human-machine interaction systems. Faced with complex operating conditions such as high shear stress and large deformation, multilayer flexible sensor devices often face technical bottlenecks such as interface delamination and signal instability. To achieve both robustness and sensitivity, a team from the Southern University of Science and Technology innovatively introduced hyperbranched polyurethane (HPU) micropillars as an interface structure, significantly improving the device’s mechanical stability and responsiveness.

In this study, the researchers successfully prepared a series of micro-column molds with different geometric parameters (diameter 50–800 µm, height 200 µm) based on BMF’s projection micro stereolithography (PμSL) technology, providing core technical support for the structural optimization of high-performance sensor interfaces.

In practical applications, the device was integrated into a robot gripper system, achieving stable grasping of a 2.0 kg dumbbell and continuously monitoring the grasping pressure during 1,000 rapid up and down movements. The signal response was stable, clearly demonstrating excellent signal stability and mechanical reliability, far exceeding traditional PDMS packaging devices.

DOI:https://doi.org/10.1016/j.matt.2025.102221

Bringing the Vision to Life with BMF’s PµSL Technology

At the heart of these innovations is BMF’s Projection Micro-Stereolithography (PµSL), a platform capable of 2-25 µm resolution that unlocks architectural freedom for microstructured interfaces, material flexibility, including high-performance resin materials, ceramic slurry and hydrogels,and rapid prototyping from design concept to refined, functional components. These breakthroughs underscore how micro 3D printing integrates structural integrity, sensing performance, and multifunctionality—far beyond what flat, layered sensors can achieve.

At BMF, we’re proud to provide the microfabrication capability that turns these ingenious designs into tangible products, empowering the next wave of intelligent sensors and smart devices.