Highlights:

- Minimally invasive and biocompatible:

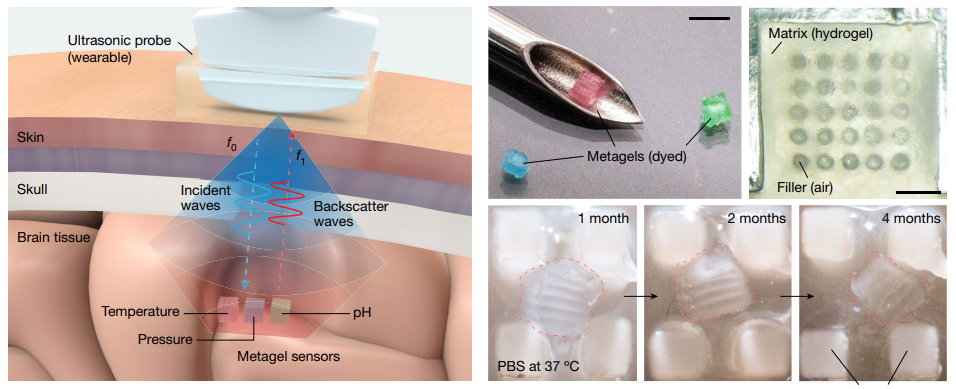

– The sensors are cubes 2×2×2 mm³ in size, providing a promising solution for intracranial monitoring

– Made of biomaterials that are compatible with human tissues, reducing the patient’s rejection reaction

- Biodegradable

– Capable of natural degradation within the human body, avoiding the burden of secondary surgery

- Multiparameter monitoring capability and high sensitivity:

Multiple signals can be monitored precisely, which is crucial for accurate clinical monitoring

In the frontier field of medical technology, precise and minimally invasive monitoring of intracranial physiological signals has always been the goal pursued by researchers. The latest research results of a joint team from Huazhong University of Science and Technology and NTU Singapore have taken this goal a big step forward. The injectable ultrasonic hydrogel sensor they developed has not only attracted widespread attention in the field of biomedicine, but also is expected to be put into practical application to benefit patients.

The relevant research results have been published in the journal Nature with the title “Injectable ultrasonic sensor for wireless monitoring of intracranial signals”.

Breaking Through Tradition, Innovative Monitoring Methods

Traditional methods for monitoring intracranial pressure usually require surgical implantation of wired sensors, which not only increases the risk of patient infection, but may also cause postoperative complications. Existing wireless electronic sensors, due to their large size, are not suitable for minimally invasive surgery and cannot degrade naturally in the body, bringing the burden of secondary surgery to patients.

PμSL 3D Printing Technology: Exquisite Carving, Achieving Innovation

High-precision 3D printing is transforming the life sciences in many unexpected ways, BMF’s PμSL 3D printing technology allows for the creation of custom components to the exact dimensions needed. The team used microArch S140 (precision:10 μm) to print the ultra-small ultrasonic sensor with a cube 2×2×2 mm³in size,then through hydrogel molding.

Ultrasonic Hydrogel Sensor: Small size, Great Performance

This ultrasonic hydrogel sensor is composed of a double-network hydrogel matrix and periodically arranged air columns inside, and its special structure has an acoustic band gap in the 8-10MHz frequency band, which has an exceptional acoustic reflective properties for incident ultrasonic waves. This feature enables the sensor to monitor key physiological parameters such as intracranial pressure, temperature, and pH accurately through minor morphological changes.

The Prospect of Clinical Application

Animal experiments have proven that this sensor can be comparable to commercial wired sensors in detection depth, while also showing great advantages in energy consumption and non-thermal effect. More importantly, this sensor is biocompatible and degradable, and can be naturally degraded about 1 month after injection into the body, without the need for further surgery to remove, greatly enhancing the patient’s treatment experience.

The application of BMF 3D printing technology in this research not only demonstrates its strong potential in the field of precision medical device manufacturing, but also injects new vitality into the development of the future intelligent medical and health field. With the further development and application of this technology, we have reason to believe that it will bring more good news to human health and open a new era of intracranial monitoring.

- For the full article, please check: https://doi.org/10.1038/s41586-024-07334-y

- For a customized inquiry, please contact us via https://bmf3dapac.com/#contact