BMF APAC and Shenzhen MultiMatter Science and Technology Co., Ltd. have joined forces to solve long-standing bottlenecks in high-end manufacturing. Their first joint result is the microCube M150 — a high-precision, multi-material photopolymer 4D printer designed for scientific research institution and industrial use.

With an optical resolution of 25 µm, M150 supports integrated processing of hard resins, elastomers, hydrogels, shape-memory polymers, conductive elastomers and other functional materials, enabling true 4D printing for demanding sectors such as biomedical, soft robotics and aerospace.

.png)

Principle Introduction of MultiMatter 4D Printing System Technology

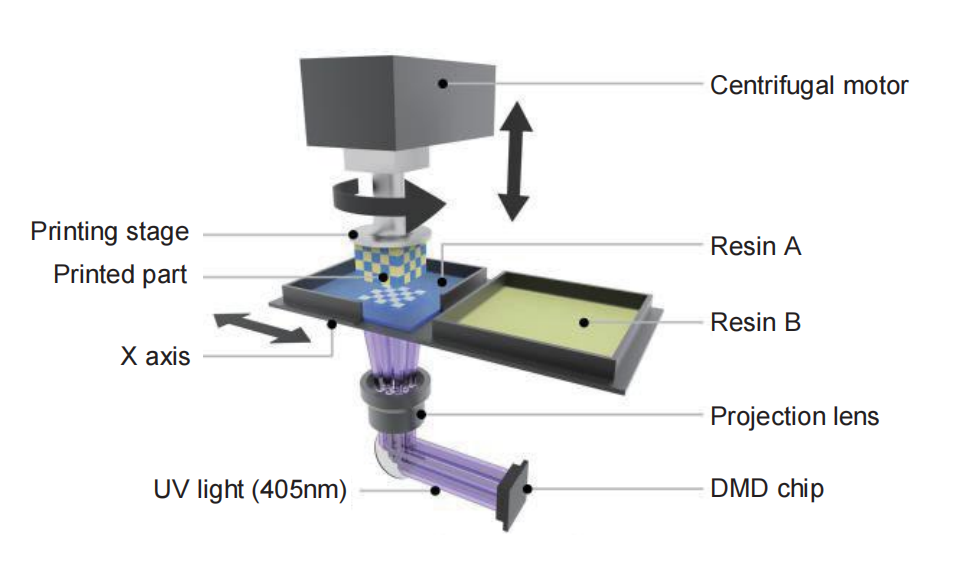

4D printing extends additive manufacturing by combining intelligent materials with 3D geometry so that printed parts can respond predictably to thermal, optical or chemical stimuli. The microCube M150 implements a centrifugal photopolymerization approach to enable robust, repeatable multi-material 4D production.

The core innovation of M150 is centrifugal multimaterial switching technology, a high-speed centrifugal action integrated into the build platform rapidly and efficiently clears residual fluids after material changes, solving the perennial problem of cross-contamination and residual liquid removal.

Four technology breakthroughs that solve industry bottlenecks

- Centrifugal multi-material switching: The centrifugal speed is adjustable, reaching up to 10,000 RPM, allowing for rapid switching in 60s.The maximum number of switching times in a single printing can reach up to 2,000, which is at the leading level in the industry.

- Dedicated multi-material slicing software:Proprietary slicer supports arbitrary spatial distribution of materials within a single model.Processing speed up to 500 slices per minute, dramatically improving data-preparation time for complex geometries and increasing readiness for production environments.

- Wide material viscosity compatibility:Supports materials across a viscosity range of 5–5,000 cps.Compatible material families include hard resins, elastomers, hydrogels, shape-memory polymers (SMPs), conductive elastomers and engineered combinations thereof — enabling a broad palette of functional 4D material systems.

- Integrated formation of multi-material, multi-functional coupled structures: Simultaneously prints up to three materials with layer-and-in-layer switching.Intra-layer transition zones <100 µm, ensuring accurate functional gradients and reliable performance coupling where different material phases meet.

Application prospects, bridging lab innovation to industrial production

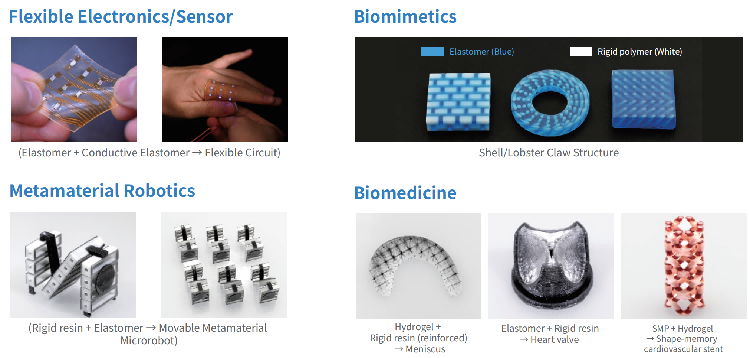

| Flexible electronics

By co-printing conductive elastomers with elastic substrates, M150 enables integrated circuit traces and flexible base substrates in one build. This eliminates mechanical and assembly incompatibilities between rigid electronics and soft substrates — a critical step for next-generation wearables and health-monitoring sensors requiring conformal, lightweight designs.

| Metamaterial micro-robots

The mixed use of hard and tough resins allows integrated manufacture of precision transmission components alongside compliant drive elements. This paves the way for micro-scale mobile robots with embedded mechanical complexity and multifunctional capabilities useful for medical micro-manipulation and environmental micro-sensing.

| Biomedical devices and tissue engineering

Combining hydrogels with reinforcing hard resins or shape-memory polymers provides novel routes for tissue scaffolds and implantable devices. The M150’s capacity to spatially control material distribution and functional gradients enables closer replication of biological microarchitectures, supporting personalized implants and smart, stimulus-responsive medical devices.

| Aerospace

Pairing shape-memory polymers with conductive elastomers allows adaptive aerospace components that sense and respond to environmental changes. Such structures can enable autonomous shape-morphing elements for deployable structures and lightweight, space-adaptive mechanisms that maintain functional stability under extreme conditions.

Pushing Boundaries with Multimaterial 4D system

The microCube M150, not just higher resolution, but the ability to co-fabricate multiple functional materials with tight control over microstructure and intermaterial transitions. By addressing both hardware and software bottlenecks, from centrifugal residue management to high-speed, multi-material slicing, the M150 delivers an industrial toolchain for customers seeking to move from precision parts to functionally integrated, intelligent products.

For companies developing wearable electronics, micro-robotics, advanced medical devices or adaptive aerospace components, the M150 offers a single-platform solution to prototype and produce highly integrated, multi-material systems at micron-level precision.

Currently, the M150 is available for customers in the APAC region only.For more information about our technologies, products, or partnership opportunities, please get in touch with us.