Micro bioprinting is emerging as a critical tool in modern biomedical research, enabling the fabrication of complex, cell-laden architectures with microscale resolution. However, achieving high fidelity in hydrogel-based bioprinting remains a major challenge, especially when working with soft, low-viscosity materials like GelMA that are prone to light scattering and unintended polymerization.

A recent study published in Nature Communications introduces a groundbreaking strategy that addresses this issue through a dual-function photoinhibiting molecule—Cur-Na, a sodium salt of curcumin. This innovation significantly enhances the spatial precision and biological performance of light-based bioprinting systems, particularly in the fabrication of highly detailed hydrogel constructs.

Light-based 3D bioprinting techniques such as digital light processing (DLP) rely on the precise projection of patterned UV or visible light to initiate polymerization in a photosensitive hydrogel. Yet, in dilute or soft hydrogels, light scattering and overexposure can lead to blurred structures, loss of resolution, and unintended crosslinking outside the focal area. This severely limits the ability to print microscale features such as capillaries or thin-walled scaffolds.

The Breakthrough: A Dual-Action Photoinhibitor

To tackle this, the researchers developed Cur-Na, which performs essential roles simultaneously:

1.Significantly enhanced printing resolution and fidelity: Under controlled hydrogel swelling conditions, the printing accuracy approaches the theoretical limit of the printer (~1 pixel).

2.Excellent adaptability to printing parameters: The method greatly simplifies the optimization process by maintaining high performance across a wide range of printing conditions.

3.Superior capability in fabricating complex scaffold structures: The technique excels at creating microscale channels and thin-walled features, which are critical for nutrient transport and oxygen diffusion within the scaffold.

4.Successful fabrication of cell-laden gyroid scaffolds sensitive to light scattering: The printed gyroid structures support robust cell proliferation, with sustained growth observed throughout the scaffold over a 14-day culture period.

5.Broad applicability across other photo-curable inks: This strategy can be extended to various free-radical chain-growth polymerizable materials, such as Sil-MA, enabling broader use in light-based bioprinting.

High-Fidelity Fabrication of Complex Structures

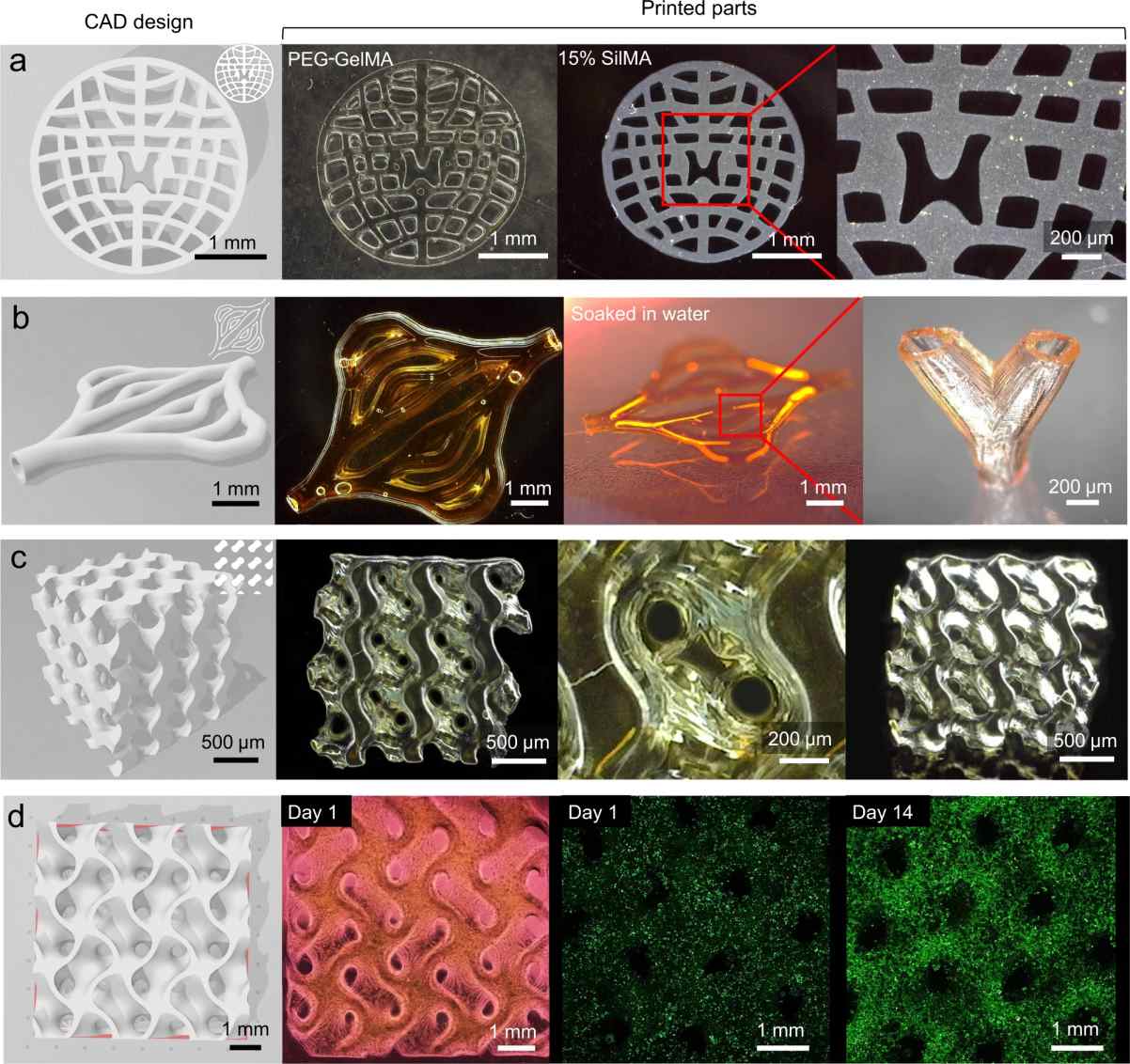

The researchers demonstrated the system’s capability to print various high-precision 3D constructs using microArch® S140(resolution:10μm), including:

1.Spinal cord scaffold with irregular channels and thin-walled networks

2.Gyroid scaffold with unique topological features

3. Vascular network with multiple branches, perfusable channels (200–800 μm) and thin walls (~100 μm)

4.Gyroid scaffold encapsulated with HepG2 cells

Importantly, these structures not only retained their geometric fidelity after swelling and washing but also supported high cell viability and proliferation, confirming the biocompatibility of the Cur-Na additive.

Enabling Next-Generation Applications

The implications of this innovation extend across several domains:

1.Tissue Engineering & Regenerative Medicine:High-resolution hydrogel printing enables the fabrication of biomimetic scaffolds that replicate native tissue environments

2.Organ-on-a-Chip & Disease Modeling: By printing microscale, multi-channel hydrogel structures, researchers can build advanced microphysiological systems.

3.Personalized Medical Devices:Combining patient imaging data with high-resolution printing enables the customization of implantable scaffolds for guided regeneration,personalized wound dressings or conformal devices.

BMF APAC x Suling Tech: Pioneering the Future of Biofabrication

BMF APAC has formed a strategic partnership with Suling Tech to jointly launch the microArch® S140 BIO, a next-generation micro-nano bioprinting system. Designed for ultra-high-resolution bio-ink printing, the system features small-volume vats (5 ml/20 ml), an integrated heating module, and live-cell printing capabilities. It achieves precision down to 10 μm, providing customizable solutions for applications in regenerative medicine, tissue engineering, drug screening, and biomedical research.

Built on BMF’s advanced PμSL technology and Suling Tech’s patented light scattering suppression method, the partnership also introduces a new high-resolution bio-ink—GelMA. With features like biocompatibility, biodegradability, and cell affinity, GelMA enables printing resolutions as fine as ≤5 μm and supports robust cell proliferation.

This video provides an overview of the blending process of the GelMA-DS series and demonstrates how high-precision structures can be fabricated using GelMA in combination with a micro-nano 3D printing system.

For more information about microArch® S140 BIO and GelMA , please reach out or leave a comment.

Conclusion

By overcoming the long-standing issue of light scattering in hydrogel-based bioprinting, Cur-Na provides a scalable and reproducible method to improve printing fidelity without compromising cell viability. As the field of micro bioprinting advances toward clinical and industrial applications, such innovations in chemistry and printing hardware together promise to redefine the possibilities in tissue engineering, personalized medicine, and biofabrication.